Password Reset

Forgot your password? Enter the email address you used to create your account to initiate a password reset.

Forgot your password? Enter the email address you used to create your account to initiate a password reset.

4 Minutes

A research team from the UPMC Department of Otolaryngology has been exploring using 3D printed temporal bone models to aid surgeons in training and case preparations for mastoidectomy, and using the 3D models in experiments designed to ascertain the experience level of surgeons performing the procedure.

Noel Jabbour, MD, MS, FACS, associate professor of Otolaryngology, residency program director, and director of the Congenital Ear Center at UPMC, and his team published findings from a recent study in The Annals of Otology, Rhinology, and Laryngology.

“While 3D printing of anatomical models for research purposes, training, and surgical case preparations have become more widespread in medical and surgical specialties, the technology and consumables required to generate the models require significant expense,” says Dr. Jabbour.

Dr. Jabbour and colleagues’ study is interesting on two fronts. They used consumer-level 3D printers and consumables to produce 3D models of temporal bones for evaluation by surgeons to see how well they replicated the anatomy and how they responded to drilling and other performative characteristics.

The study also is the first to use 3D models to gauge an otologic surgeon’s experience level conducting a procedure.

Former department resident Monika Freiser, MD, MPH, was the first author of the study and led the investigation’s efforts.

Anish Ghodadra, MD, now an assistant professor in the Department of Radiology at the University of Pittsburgh School of Medicine was instrumental in the study’s design and execution while a resident. He is currently the Medical Director of the 3D Printing Program at UPMC, a facility that first began to form at the time this investigation began, and he served as the Director of the 3D Printing Laboratory during his final year of residency.

Consumer-level 3D printing technology is significantly less expensive when compared to the typical industrial-grade equipment and printing media typically used in anatomic model generation. Industrial-grade printers cost well above $15,000. Dr. Jabbour’s team used a high-end consumer model costing $3,500 and were subsequently able to produce anatomic models for a raw materials cost of $10.00 per model.

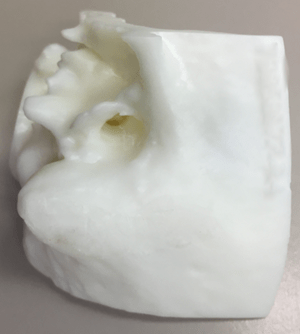

The model before surgical drilling.

The team then produced models and had second-year and fifth-year residents and attending surgeons assess the models for performative characteristics and usability in preparing for a case of mastoidectomy with facial recess. The models were all generated from the same CT scan data from a 7-year-old patient.

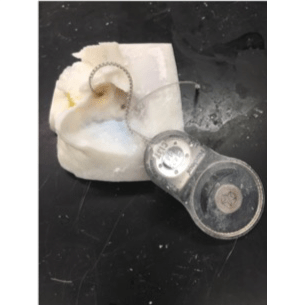

Residents and faculty in their surveys all scored the models favorably in their utility for training and preparing for a case. They also noted the favorable drillability of the acrylic resin used to create the models. Surgeons testing the models also noted favorable vibration properties and overall similarity to native anatomy. However, reviewers noted the acoustic properties of the models did not change during drilling due to the uniform density of the material not replicating the varied densities encountered in actual cases. This was also the case regarding the material's color and tactile response during drilling.

“This type of consumer-level 3D printing can be effective at preparing anatomical models for case preparation in a much more cost-friendly manner. It has the potential to greatly expand the use of this type of modeling to help surgeons prepare for these delicate surgical procedures,” says Dr. Jabbour. “Some of our future work will be focused on how to create even more precise and anatomically correct models.”

3D printed temporal bone being used to practice cochlear implant placement.

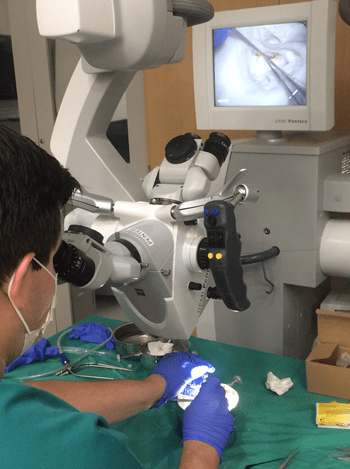

Models from the residents and attending participants were each graded blindly by six attending surgeons with regular experience performing mastoidectomy. They graded the models on two main characteristics: satisfaction of the exposed named structure and the presence and size of drilling defects in the named structures.

The scoring of the models showed a clear distinction in performance between second- and fifth-year residents and experienced attending surgeons.

Second-year residents showed the most variability in performance measures and received the lowest scores. As one would expect, fifth-year residents performed better than second-year residents but showed a significant gap between experienced attendings. However, the results also showed a decreasing rate of performance variability as the surgeon's experience level increased, indicating that the model and its assessment for performance could discriminate between groups.

Using the models in a national course for pediatric otolaryngology fellows.

“With additional research and validation, this approach to using models in simulation and training can help gauge surgical expertise more quantitatively, using standardized and validated modeling scores to more objectively assess surgical performance and skill,” says Dr. Jabbour.

Read the full paper and its findings using the link below.

Freiser ME, Ghodadra A, McCall AA, Shaffer AD, Magnetta M, Jabbour N. Operable, Low-Cost, High-Resolution, Patient-Specific 3D Printed Temporal Bones for Surgical Simulation and Evaluation. Ann Otol Rhinol Laryngol. 2021; 130(9): 1044-1051.